On the dot: VC Smart Reader from Vision Components reliably detects data matrix codes

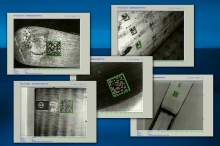

Figure: The VC Smart Reader ensures quick and reliable Data Matrix recognition,

reading even incomplete (left) or blurred (right) codes

Vision Components offers a wide range of real-time, network-capable Smart Cameras for the implementation of high-performance 2D code recognition systems. The VC Smart Reader software has been optimized for use with VC Base, VC Professional, VC Optimum, VC Board Cam, and VisiCube camera types. It features three operation modes: the “Auto Mode” requires no configuration efforts and enables the detection of a wide range of codes; the “Teach-In Mode” allows users to read in one sample code and save its parameters in a list; and the “Parameter Adjustment Mode” allows for manual adjustment of parameters to improve software performance. The VC Smart Reader now also includes quality parameters such as ISO/IEX15415 and AIM DPMI-1-2006, which further facilitate the integration of the vision systems. Registered users can download a VC Smart Reader demo version and the manual, which provides many illustrated examples, at www.vision-components.com.

Company Background

Vision Components GmbH, founded in 1996 by Michael Engel, inventor of the first intelligent camera for industrial applications, is a leading supplier in the field of machine vision. Branches and distributors represent the Ettlingen-based company worldwide in more than 25 countries. Vision Components develops and distributes intelligent, network-compatible real-time Smart Cameras, which are able to operate without a PC and can be integrated into almost any industrial facility. Typical applications include quality inspection and automation. Equipped with the proprietary multitasking VCRT operating system, VC Smart Cameras can be easily configured for all possible tasks. Furthermore, VC provides software libraries for a wide range of applications including motion capture, decoding, measurement, and positioning. Additionally, VC develops custom-tailored solutions for specific tasks such as wafer handling in the solar industry or OEM camera modules for medical devices technology.