HUEVIEW™ TECHNOLOGY OFFERS UNPRECEDENTED LEVELS OF COLOR AND TEXTURE

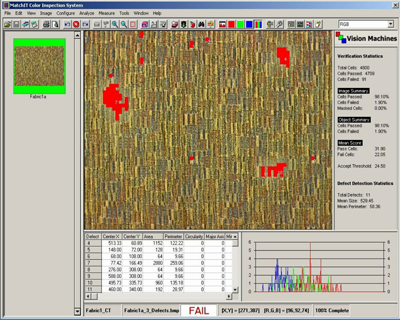

Used to measure color (in RGB, HSI or LAB space) and texture, monitor product appearance, classify/grade goods, facilitate sorting operations, assess visual similarity or detect defects, by comparing images of items or scenes of interest to their respective stored reference images, HueView optimizes its flexibility, accuracy and repeatability by operating at high spatial resolutions and enabling inspections to be done based on color, texture or a user selectable combination of the two. Allowing texture analysis to be factored into inspections as required ensures that items possessing sufficiently similar color content but featuring varying mixes of multiple colors or subtle defects in their patterns can still be identified as aberrant or of unsatisfactory appearance.

HueView is currently available in the form of an easy-to-use WinTel-compatible software application that supports image acquisition using FireWire cameras, TWAIN and analog camera/framegrabber combinations, eliminates the need for programming, is quickly trained by simply being shown reference examples, incorporates powerful pattern recognition and learning capabilities and requires no follow-up data analysis. The level of interest expressed by software developers will determine whether the technology becomes available in a form suitable for implementation by those ready, willing and able to create their own application programs.

A typical solution consists of the existing software application running on a PC that features a Pentium 4 processor operating at ? 3.0 GHz, a light box, industrial microscope, camera stand or online setup and an appropriate camera, optics and illumination configuration.

Applications include inspection of materials in general (textiles, leathers, papers, composites, plastics, metals), inspection of building/renovation materials in particular (tile, carpet, granite, marble, wood, countertops, paints and stains, wallpaper), inspection of food (meats, fruits & vegetables, cheeses, baked goods), inspection of consumer goods (cosmetics and jewelry) medical (dermatology, pathology, dentistry, pharmaceuticals), manufacturing operations (lot matching, material optimization, wear testing, thin film interference pattern analysis, thermal analysis, etc.), graphic arts (color printing and reproduction, proofing), scientific investigation (microscopy, fluorescence, forensics), image-based database retrieval and analysis of artwork.